Oil, Gas & Mining Fleet Tracking

Manage your fleet vehicles, equipment, and workers across remote job sites in challenging environments with our mining fleet management software. Track performance, optimise resources, and enhance safety, all while reducing costs and boosting productivity.

Strengthen safety protocols in your mining fleet with advanced tracking and management.

Our mining fleet management software provides real-time visibility into your fleet’s location, safety, and performance, no matter how remote the site. With advanced tracking and analytics, you can effectively monitor safety protocols and equipment usage, ensuring high safety standards and optimised operations wherever your fleet operates.

What is oil, gas and mining fleet management?

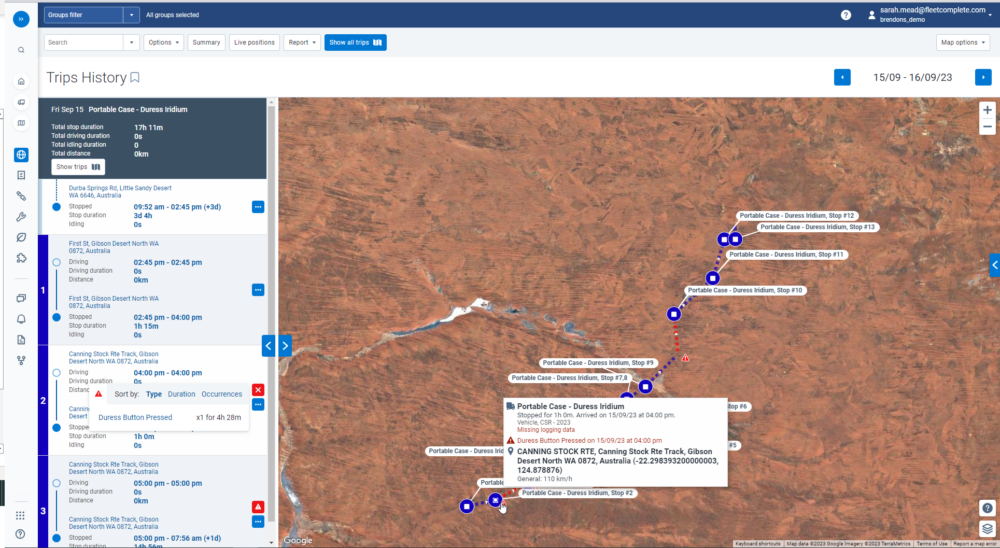

Fleet Complete’s Iridium Satellite Module keeps your vehicles connected beyond cellular coverage, ensuring continuous tracking and communication, with data logged and ready to report when back in range.

Quickly respond to emergencies with Fleet Complete’s dash-mounted duress buttons and driver remote pendants. Manually activated by the operator, these devices ensure immediate alerts for accidents and emergencies, enhancing safety across your fleet.

Enhance safety and accountability with Driver ID. This feature allows you to accurately track who is driving each vehicle, providing real-time visibility and eliminating uncertainties, especially when employees operate multiple vehicles.

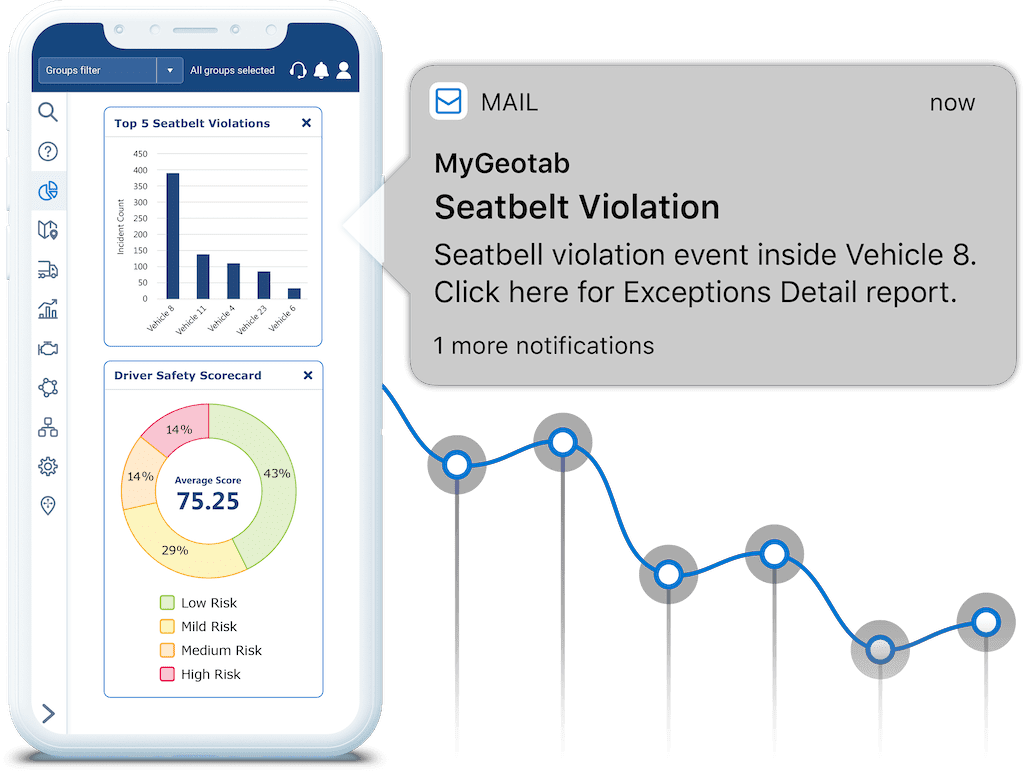

Long remote journeys can lead to risky behaviours in the mining and oil and gas sectors. Monitor harsh driving, seat belt use, and speeding. Generate safety scorecards or alerts to ensure your team’s safe return, enhancing safety in your mining fleet management.

Integrated Solutions for the Oil, Gas and Mining Industry

When operating in Mining and Oil & Gas industries, your fleet needs are drastically different. Safety, compliance and data-driven precision are key, especially in remote areas.

Frequently Asked Questions

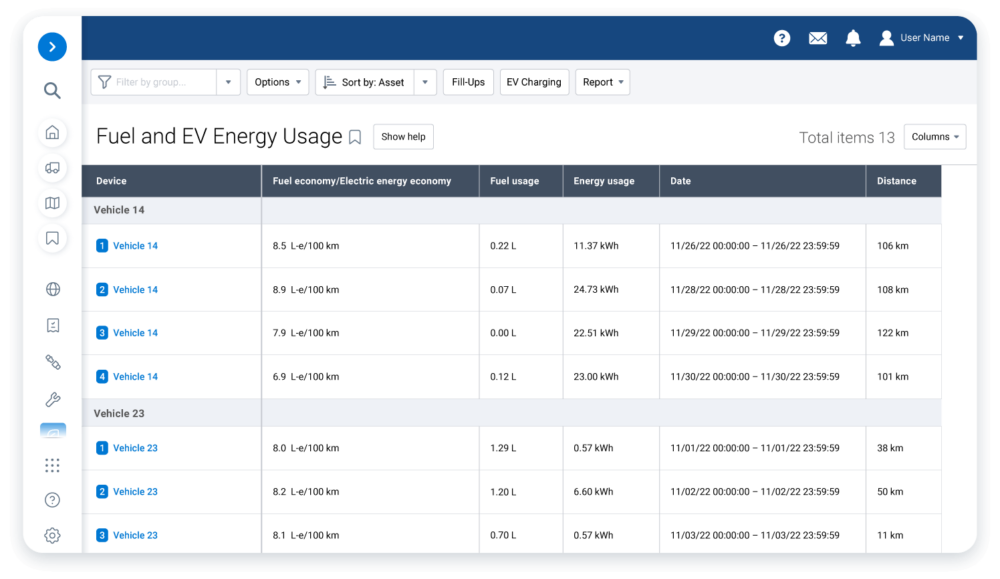

Fleet management in the oil, gas, and mining industries involves the coordination and optimisation of vehicles, heavy equipment, and other assets used in these sectors. This includes tracking the location, usage, and maintenance of fleet vehicles and machinery, ensuring safety and compliance, managing fuel consumption, and improving operational efficiency. In such challenging and often remote environments, fleet management also focuses on real-time monitoring, predictive maintenance, and integrating technology to minimise downtime, reduce costs, and ensure the safety of workers and assets.

Fleet management enhances safety in the oil, gas, and mining industries through several key strategies:

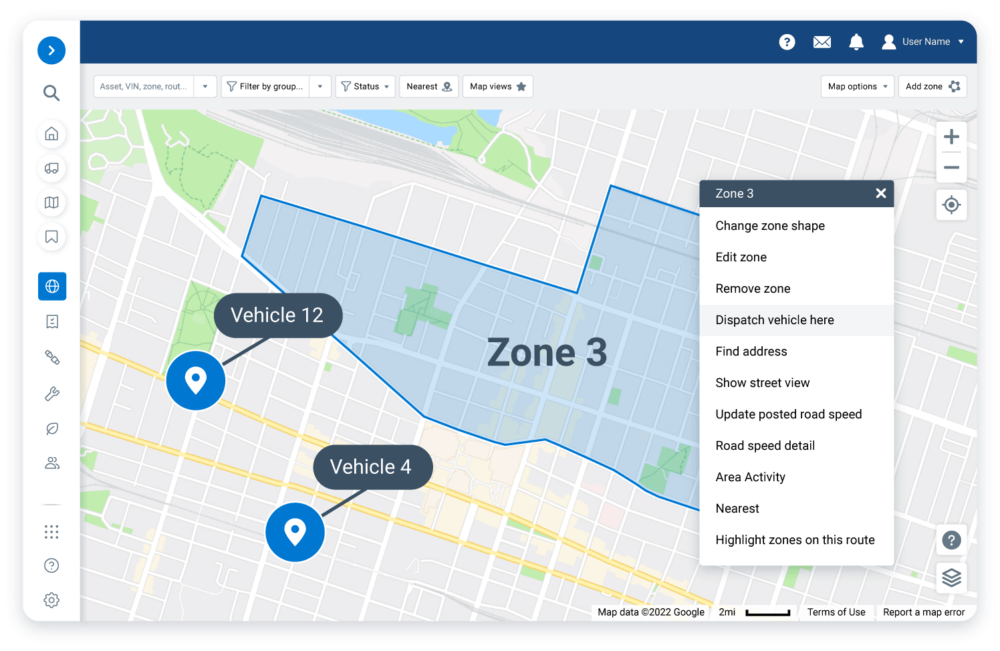

- Real-Time Monitoring: Continuous tracking of vehicles and equipment allows for immediate response to unsafe conditions or incidents, helping to prevent accidents in remote and hazardous locations.

- Predictive Maintenance: By monitoring engine health and equipment usage, fleet management systems can predict when maintenance is needed, reducing the risk of breakdowns or failures that could lead to dangerous situations.

- Driver Behaviour Tracking: Fleet management tools can monitor driver behaviour, such as speeding, harsh braking, and seat belt use, and provide feedback or alerts to encourage safer driving practices.

- Emergency Alerts: Systems can include features like duress buttons or automated alerts that notify management of emergencies, allowing for quicker response times and ensuring workers’ safety.

- Regulatory Compliance: Fleet management ensures that all vehicles and equipment meet safety regulations and standards, reducing the risk of accidents due to non-compliance.

- Journey Management: Planning and monitoring routes help minimise risks associated with long journeys in remote areas, ensuring that vehicles and personnel reach their destinations safely.

By integrating these features, fleet management systems help create a safer working environment in the demanding sectors of oil, gas, and mining.

Fleet management in the oil, gas, and mining industries involves tracking a wide range of assets, including vehicles, heavy machinery, powered equipment, and non-powered assets. This is achieved using telematics devices that utilise GPS, sensors, and satellite communication to provide real-time data on location, performance, and maintenance needs. For example, in mining, excavators and haul trucks are tracked to monitor usage, prevent breakdowns, and ensure safety. On oil rigs, the tracking of drilling equipment and support vessels is critical for maintaining operations and worker safety. By providing continuous monitoring and data analysis, fleet management systems help optimise operations, reduce downtime, and enhance safety in these challenging industries.